Management Policy

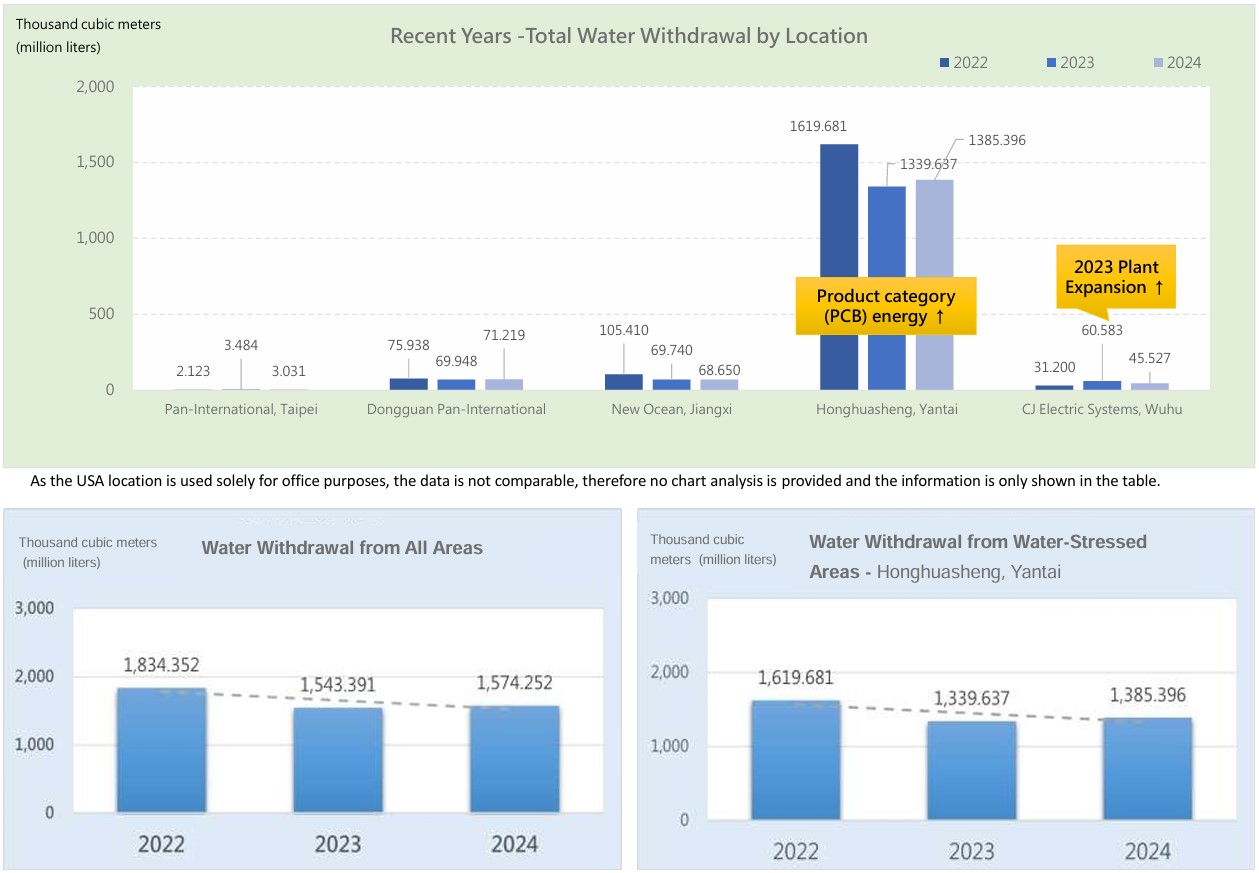

The primary water sources of the Group’s key subsidiaries in China (with production plants + 100% operational control) all come from local water companies in China, with water sources from reservoirs. Except for Honghuasheng, Yantai, which is in a water-stressed area, water withdrawal at other locations comes from non-water-stressed areas or protected areas, with little impact on water sources.

The Group’s Dongguan Pan-International, New Ocean Precision Component, Jiangxi, and CJ Electric Systems, Wuhu do not cause significant environmental impacts from water withdrawal and wastewater discharge. The production wastewater generated does not reach industrial wastewater treatment standards and is treated as domestic water, which is then directly discharged into the urban sewage network for collection and treatment at sewage treatment plants.

As the Honghuasheng, Yantai plant’s process involves PCB process water, and the industrial wastewater produced is treated through the on-site sewage treatment plan, which complies with local regulations. The wastewater is treated to meet the domestic discharge standards before being released into the urban sewage network for further treatment. In terms of water conservation, we continuously optimize processes to improve water recycling and reuse rates. Currently, after implementing improvements, wastewater generated from pure water production is reused as recycled water, achieving a recycling and reuse rate exceeding 10%.

For wastewater discharge management, each plant obtains permits from the government in accordance with local regulations and performs basic on-site treatment. Once the wastewater meets discharge standards, it is released into the government’s sewage network for further treatment by government-commissioned agencies.

We continue to vigorously promote and implement water-saving policies, aiming to achieve water reduction goals in the future.

<< For details, please refer to: The latest version of the ESG Sustainability Report Chapter: Environmental Friendly >>